KQLS Multi layers mechanical automated parking system

It's popular as safety and fast. Stake cars to 2-8 layers depends on conventional parking slot arrangement. Adopt motor driving with chain or steel rope transmission system, stacking car by lift and sliding pallet. Every sliding layer leaves a free space for other layer pallet lifting. Every unit runs independently and optional capacity per unit effectively controls the peak time car flow. PLC program help modern management requirement. 7 times load rate and covered with multiplex electric protection to ensure safety.

Advantages:

1. Simple structure, low cost, easy operation/ installation /maintenance.

2. Suitable for basement parking, over ground or with pit, can make 2-8 layers.

3. Very flexible to assemble and disassemble, freely distribution and combination.

4. Security protection: Anti-falling hook, E.Stop, over limit protection devices.

5. Multiple operation modes, including card reading, keypad and manual mode help management and charging.

6. Easy assemble and disassemble.

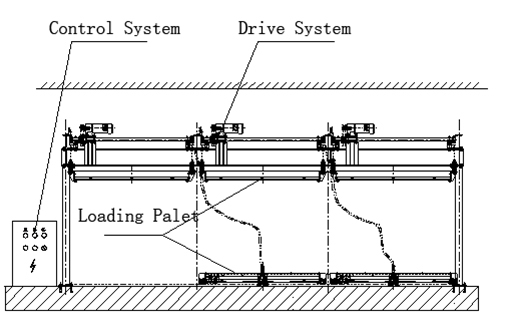

Components:

It contains 5 main parts: 1.control system; 2.drive system; 3.loading pallet; 4.steel structure; 5.safety devices.

Working Principle:

1. Stacking car by lifting and sliding pallet.

2. Every sliding layer leaves a free space for other layer pallet lifting.

Technical Parameters

Technical drawings of 3-layers lift sliding parking system:

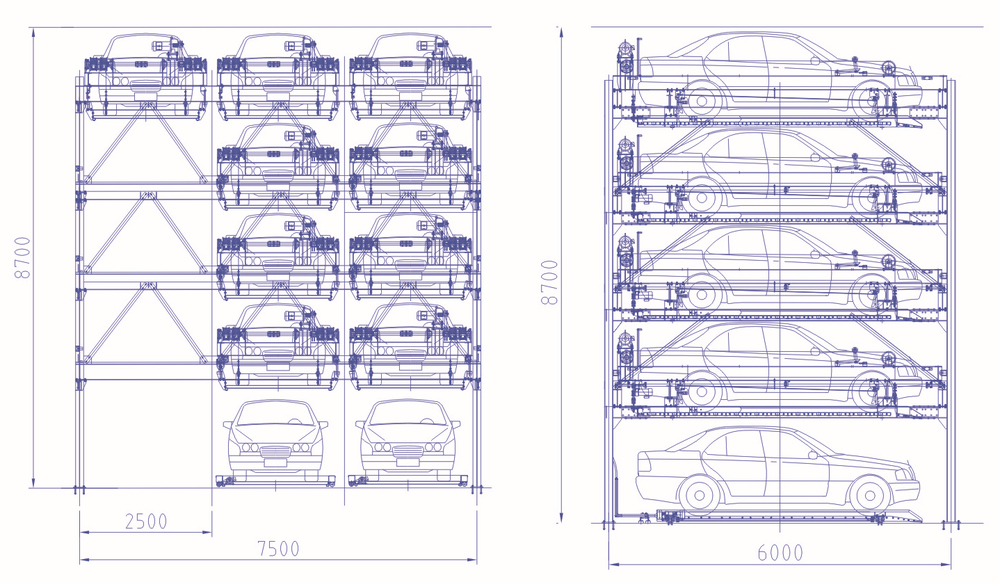

Technical drawings of 5-layers lift sliding parking system:

Design parameters of Multi-layers puzzle parking

Steel Structure

1. 7 times of safety factor.

2. High strength bolts for connecting.

3. Expand screw embedded for firmness.

4. Flexible for disassemble and transportation.

5. Anti-corrosion treatment for the surface.

Lift System

1. Lift motor is Taiwan Brand-"Mingchun" with high safety and low noise.

2. Chain wheel adopts NO.45 steel material,high strength,hardness&wear resistance.

3. "16 A" roller chain by high temperature treatment with low noise, sensitive action, accurate transmission ratio.

4. In the transmission process,reduced friction between chain and sprocket prolongs the service life of them.

Sliding System

1. Sliding system consists of the moter, sliding palet and guide rail.

2. Sliding motor is Taiwan brand-"Mingchun"; helical gear reducer motor is 0.2KW.

3. Corrugated palet ensure the car's stalility in the rise and fallprocess.

4. Guide rail ends with overtravel protection.

Control System

1. PLC: "Omron" brand

2. Electric components: "Schneider" brand

3. Adopt RISC principle: cost saving, power enhancement, very high price ratio.

4. Programmable logic controller (PLC) and friendly operation interface.

5. The control system includes six parts: the low pressure control section, the logic control part, stroke control part, entrance control part, user operation control part, the operative part.

Loading Pallet

Assembled corrugated galvanized pallet--Blasting surface treatment: Throws the pill to eliminate the rust.

Safety Device

Anti-falling hook; Emergency stop switch; Over limit protection devices; Alarm light; Catch wheel rod; Prvent people from access; Control of operation porcess; Power cut braking portection; Running interlocking device;

Electrical System

1. Total control switch-open, Schneider C65N;

2. PLC host computer and extension module--Japan, Mitsubishi FX series

3. Phase sequence protection-- Jiale DPA51CM40;

4. AC contactor-- Schneider LC1 series;

5. Thermal relay-- Schneider LR2 series;

6. Intermediate relay--Omron MY4J;

7. Fuse, maintenance socket,terminal row,indicating lamp;

Our Services

After-sales Services

DS Auto parking offers service for all of its installed machines. The machines come with a one-year parts and labor warranty and thereafter the owner has the option of extending the warranty or just continuing with service.

Service Features

I-"Complete & Integrated park solutions"

1.Excellent before-sales services

2.Flexiable garage design

3.Customized solutions

4.Manufacturing reliable products

5.Fast delivery-quick installation-final test

6.Trustworthy support and maintenance

II- "One to one lifetime close service"

1. "One to one"--Provide every customer 1 service consultant, through 12 service stations.

2. "Lifetime"--To the equipments, to the customers.

3. "Close"--Besides the related affairs, concerned about lives of customers,to form "close friend" relationship.

III-"Long term win-win corporation"

1.With exceptional quality,win the customer's credit & reliablity.

2.Offer customers all-around tailor-made solutions to satisfy user's diverse requirements, build long-term corporation,accumulate rich experience.

Training Measures

For every project, we provide Corresponding training:

I-With the combination of theory and practice, we provide training during on-site installation and commissioning period.

II-Customers should arrange full-time person to be trained. There are two types of the training:

1. Operation training—we ensure that workers can operate the garage systems correctly, use various functions of the garage, and could deal with various emergency situations.

2. Repair training—we ensure that the workers know how to carry out regular maintenance, can handle some common breakdowns.

III-The training includes the structure & electrical principle, usage and repair, daily management etc. Teaching materials include construction layout, component assembly drawing, after-sales service specifications etc.

IV-Arrange workers to participate in the test to ensure their skills.

Our Projects